|

Knitted wire over elastomer core - now UL 94-V0 recognized Cost effective EMC gasket meets fire protection requirements

By Matthias Meyr, Director Sales & Marketing Europe, Laird Technologies, Germany

Beside the request of electric conductivity and environmental protection of gaskets, the request for flammability ratings according UL94-XX becomes more and more important. This requirement occurs mainly if the final equipment is supposed to be exported into the U.S. of America.

Especially at complex IT- and Telecommunication applications this request is taken very seriously. Laird Technologies has developed over the last years a variety of gaskets corresponding also to this requirement. One of the latest improvements has been made on the ElectroNit® product line.

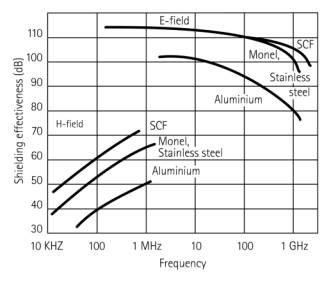

Temperature resistant all metal knitted wire mesh Knitted wire mesh gaskets are available in a variety of constructions and profiles. They are available as all mesh knitted gaskets, wire knitted over an elastomer core, or as combination gaskets (knitted wire mesh gasket bonded to an elastomer strip).

UltraFlex® ElectroNit® combines the optimum mechanical properties of beryllium copper with shielding effectiveness as much as 20dB higher than conventional materials. It offers superb resiliency for consistent, point-to-point contact requiring the lowest compression forces among all other shielding materials and configurations. A wide range of platings, sizes, configurations, and excellent flexibility create optimum design latitude.

Figure 1: All Metal Mesh gaskets can be used for applications where temperature resistance requirements are up to 800°C.

Figure 2: Typical shielding performance of knitted wire gaskets.

Knitted wire over elastomer core - now UL94 recognized Until now, it has been almost impossible to produce knitted wire over elastomer core which meets UL 94 requirements. Historically, this is why many customers have not used the knitted elastomer in EMC-shielding solutions, despite offering an impressive price-performance ratio.

Laird Technologies has recently been successful in meeting the requirements for UL-recognition. A certificate confirms the compliance with UL94-HB up to a material thickness of 2.0 mm, for a material thickness above 2.0 mm the gasket meets the criteria of UL 94-V0. The basis of this is a special TPE foam developed by Laird Technologies which exhibits excellent fire retardant properties.

The standard gasket type consists of two layers of wire knitted around the foam core, and provides the customer with a selection of six different wire types for optimum shielding performance and galvanic compatibility. The following types are available: Beryllium Copper (alloy 25), Monel (alloy of copper and nickel), stainless steel, SCF (copper-plated steel core with a tin coating of 2 %), aluminium and tin-plated copper wire (SnCu). This wide material selection will provide the optimal galvanic solution with every mating material.

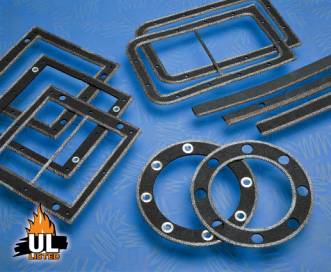

Figure 3: First time with UL94 listing: Knitted wire over TPE-Foam

Wide variety of other combinations As well as TPE, our range of core materials include neoprene, EPDM, silicone and PU foam. For very soft gaskets one layer of wire can be knitted around a PU-foam core.

Excellent price-performance ratio and a wide range of application possibilities These gaskets exhibit outstanding shielding effectiveness and have a surface resistance below 1ohm/cm. With an excellent price-performance ratio, low compression set and the simple attachment method, these gaskets are the ideal EMC shielding solution for different requirements. They remain permanently elastic and are therefore especially suitable for high cycling applications like doors and covers. The wire material penetrates oxide layers on the parent material and thus enables stable conductivity. Furthermore, protection against dust and circulating air is guaranteed.

These gaskets are used in many applications, from door seals, gaskets for side walls, rear walls, roof and floor panels to gaskets for cable entries, cover plates and lid gaskets. They also provide an excellent solution for moving enclosure parts, honeycomb filters, shielded windows and various other applications. The variety of gaskets enable simple use, avoiding the requirement for major modifications to existing enclosures.

The standard gasket profiles are rectangular and solid and hollow O-strips (with single or double mesh fins). Custom-made profiles can be produced on request. As a general guideline, optimum shielding is achieved by compressing the overall gasket by 25 %. This, however, depends on the core material and gasket profile.

It is possible to produce cut-to-length gaskets cost effectively. The gaskets are cut to a desired length and the edges are sealed in order to prevent fraying. As an option, a non-conductive self-adhesive tape can be used to aid attachment to the application.

Combination gaskets Combination gaskets consist of a sponge elastomer strip bonded to a knitted wire gasket. They offer dual functionality of good EMI/RFI shielding and also environmental protection (IP -International Protection) values up to IP 54. In addition, the recently developed TPE core gaskets also comply with the fire retardant requirements according to the UL94-standards.

Combination gaskets are available in continuous lengths (on reels), cut to length or as custom-made die-cut parts. The majority of these gaskets are supplied with the elastomer section containing a double-sided adhesive tape for easy gasket attachment. The variety of gasket mesh/elastomer combinations is vast. Another feature offered to ensure a pre-defined gasket compression are compression stops (in most cases an aluminium or brass shim). These limit the gasket compression to the desired height.

Combination gaskets are mainly used as gaskets for side walls, roof and floor panels of enclosures and cabinets and cover seals for enclosures and equipment. They are also particularly suitable for connector gaskets for large connectors, gland plate gaskets and gaskets for shielded windows and air vent panels. Combination gaskets enable shielding solutions requiring both high EMI shielding effectiveness and a high degree of environmental sealing.

Figure 4: ElectroNit® EnvironSeal gaskets: foamed elastomer combined with knitted wire mesh gasket Which gasket for which purpose? Firstly, wire mesh type should be selected to achieve the best galvanic compatibility with the enclosure. Furthermore, the required conductivity (also regarding long-term stability) has to be taken into consideration.

The gasket type and profile should be selected depending on the allowable attachment method, the space available for the gasket and on the shielding requirements. If higher shielding values are required, a double O-strip might, for example, may be recommended. The gasket height selected depends on how much the gasket is to be compressed and which tolerance range has to be compensated.

For maximum shielding effectiveness and gasket performance, mating surfaces should be free from grease or dirt to minimise gasket/ enclosure interface impedance. For further information contact: Laird Technologies GmbH, Äußere Oberaustraße 22, D-83026 Rosenheim, Germany. Tel:+49(0)8031/2460-0, Fax: +49(0)8031/2460-50 mail@lairdtech.de, www.lairdtech.com © Laird Technologies, 01/2003

|