The HP Way

Enduring Values through Changing Times

Enduring Values through Changing Times

The HP way certainly sets an example that others could do well to follow, no doubt there will be some that say; yes but HP can afford it. The answer to that being, it is because of their philosophy that they can afford it.

So what is the HP way. It began in the very early years of HP Bill Hewlett and Dave Packard, two Stanford engineers, combined their product ideas and unique management style, and formed a working partnership.

After many successful products and amidst a rapidly expanding organisation, they met in 1957 with their key managers to formalise a set of Corporate Objectives. These objectives, along with underlying corporate values that shape how the objectives would be met, remain as the foundation for something special - the HP Way of doing business summarised in a quotation by Bill Hewlett in 1982:

"What is the HP Way? I feel that in general terms it is the policies and actions that flow from the belief that men and women want to do a good job, a creative job, and that if they are provided the proper environment they will do so."

Certainly the proliferation of regulations throughout Europe and the rest of the world put the philosophy and culture to the test.

Slide 1 |

Slide 2 |

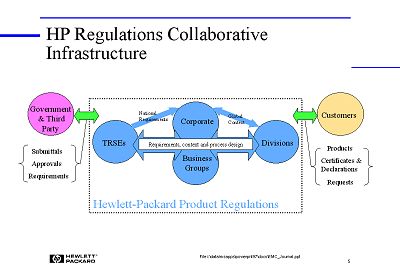

At South Queensferry the Product Regulatory Team is responsible for the full implication of the EMC, LVD and Product Safety regulations through a product's life cycle. This necessitates becoming involved at a very early stage in the Product Design process. All product testing is carried out in-house; Pre-compliance, Compliance Testing and the generation of Technical Documentation, with occasional outside assistance when resources are overloaded. Needless to say the myriad of changes to regulations causes its own problems and to cope HP has implemented a production change control process which reviews all changes to regulatory compliance and redefines processes as required. All product enhancements are treated as new products. Regulation and Standards' changes are managed throughout the product's lifetime. All regulatory documentation is archived for a least 10 years after a product has been removed from production.

The illustration clearly indicates a proliferation in regulatory requirements. The increased value is questionable so how do you optimise the value of products to ensure all round benefit.

A Global OpportunityBased on 3 concepts.For Electronic products regulations¹ of Safety and Electromagnetic Interference (EMI):

²Supplier's declaration of conformity as an regulatory option to the third-party certification option.

|

Use internationally accepted standards from ISO and IEC. Work to eliminate local and national deviations and unique requirements.

Provide for one-time testing of a given product by either the supplier or third-party test facility conforming to ISO/IEC Guide 25, without restriction on location.

Allow for Supplier's Declaration of Conformity option.

Example, publicly available documents, Web, publications, seminars, etc.

Example, audits SDoC elements and compliance folder, investigates complaints, cites penalties of violators, and public registry of violators.

Guidance on how governments should reference internationally-accepted standards.

Standard on what are the requirements and content of a Compliance Folder and a Declaration of Conformity.

Guidance on market surveillance methods that a government should consider.

ISO/IEC Guide 22, 25 and 'to be developed' international and administrative requirements.

Timely response to known violations

Provide improvements to internationally-accepted standards and SDoC requirements.

Alan E Hutley, Editor

The visit to HP by myself and Dave Fynn, was even more interesting as we have both spent over ten years with Tektronix whose slogan at that time was "committed to excellence", a department in which HP are certainly not lacking. We would like to thank, Brian Dougal, EMC Product Line Manager, EMC Marketing Organisation; Colin McGeehan, Product Regulations Specialist; David J Morrison, Processes & Regulations Manager; Bill Pike, Systems Engineering Manager; Robert Tait, Product Regulations Specialist; Geoff Thow, General Manager, Telecomms Networks Test Division, who made our visit extremely interesting and for supplying the information contained in this article.

|

In a future issue of the UK EMC Journal, Dave Fynn will be featuring HP's EMC Spectrum Analysers and EMC software. |

© Nutwood UK Ltd 2001 |

Eddystone Court - De Lank Lane St Breward - BODMIN - PL30 4NQ Tel: +44 (0)1208 851530 - Fax: +44 (0)1208 850871 nutwooduk@nutwood.eu.com |

|

|

|